Industrial laser applications

Industrial laser applications

ILA (Industrial Laser Applications) is the bridge between research and industry. We specialize in applied research in laser processing and the development of new technologies tailored to customers in a wide range of industries, from smart manufacturing to space to defense. Our work has a direct impact – we turn scientific ideas into industrial solutions. We’re a team of innovators who connect cutting-edge technology with practical applications, and we want nothing less than to do it the best in the world.

LSP - Laser Shock Peening Team

LSP - Laser Shock Peening Team

Laser Shock Peening technology utilizes short laser pulses to mechanically form metallic materials and extend their fatigue life.

We strive for a real impact on the world around us, which is why we primarily focus on practical applications in Czech and European industry. Within our team, we value a relaxed, friendly atmosphere and a safe environment, where we are not afraid to admit when we make a mistake or don’t know something. We don’t adhere to a rigid hierarchy of positions or opinions.

If someone has an idea, they can speak up, and at the end of the day, the best and most elegant solution wins – without unnecessary egos. We place a strong emphasis on personal responsibility and proactiveness, giving everyone the opportunity to fulfill themselves personally and professionally in their own way.

As a team, we strive to be involved in broader HiLASE activities such as public outreach events or the development of the internal workplace culture.

More about LSP.

LIDT - Laser Induced Damage Threshold Team

LIDT - Laser Induced Damage Threshold Team

We test laser optics so you don't have to. We make sure your system stays safe and performs at its best.

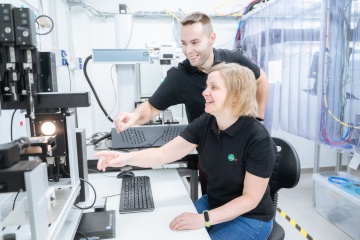

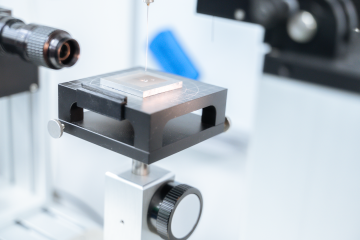

The Laser Induced Damage Threshold (LIDT) team at HiLASE focuses on bridging the gap between cutting-edge laser research and industrial needs. We specialize in testing the durability and reliability of optical components under high-power laser exposure, helping to define and expand the safe operational boundaries of modern laser systems. Our team is at the forefront of methodology development for LIDT measurements, exploring new laser radiation regimes from femtoseconds to continuous wave (CW) conditions. By using various spatial beam profiles (Gaussian and tophat), we simulate realistic use cases to support both internal and external partners.

We work closely with laser micromachining teams, space optics developers, and semiconductor industry clients, offering tailored testing, damage evaluation, and process window definitions. The LIDT team runs the popular LIDT Challenge, giving producers and users a benchmark to verify their optical components’ performance. Our growing semiconductor branch focuses on laser-matter interaction experiments, including annealing, drilling, and activation. In total, our team of six includes specialists in laser alignment, beam diagnostics, confocal microscopy, and additional materials analysis techniques such as Raman and XRD.

We collaborate with all teams at HiLASE and actively contribute to international projects with partners in Vilnius, Marseille, Jena, Stuttgart, Fort Collins, and beyond. We foster a friendly and collaborative team atmosphere, where knowledge sharing and mutual support are second nature – especially from senior members toward newcomers. We’re always on the lookout for new talent!

We’re excited to meet young, eager-to-learn individuals who are passionate about new technologies, as well as experienced professionals ready to contribute their expertise to the HiLASE goals.

Read more about LIDT.

LMM - Laser micromachining Team

LMM - Laser micromachining Team

We operate at the frontier of what's possible – our team uses cutting-edge lasers to structure materials with microscopic precision.

Our results are applied in high-tech industries, scientific research, and medical technologies.

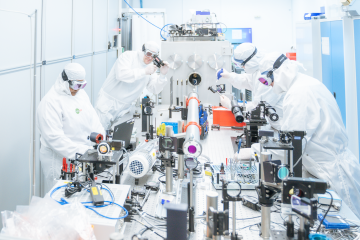

With extreme accuracy, we create micro- and nanostructures that tailor surface properties – improving adhesion, enabling antibacterial effects, or controlling wettability. We work with top-tier equipment: femtosecond lasers, spatial light modulators, diffractive and microscopic optics, beam splitters, high-precision linear and rotational stages, 5-axis positioning systems, robotic arms, high-speed cameras, and advanced sensors integrated into AI-driven process control.

We collaborate with Czech and international companies in areas like laser polishing of 3D-printed metal parts, strengthening adhesive bonds, micro-drilling, boosting battery electrode efficiency, or developing biocompatible and antibacterial implants. Our technologies are also used in the automotive, aerospace, and semiconductor sectors.

We focus on scaling up these processes – parallelizing laser machining with up to 40,000 beams and implementing smart quality control with sensor networks and artificial intelligence. We hold several world records and aim to become a global leader in laser micromachining.

If you’re looking to combine advanced technology, creativity, and real-world impact – join us, and help us shape the world micrometer by micrometer.

More about LMM.

SPACE - Laser Space Technologies Team

SPACE - Laser Space Technologies Team

Laser Space Technologies is a research team developing cutting-edge laser technologies for space - from laser optics testing, thru optical communications to 3D printing and power beaming.

Thanks to our unique experimental infrastructure and the use of state-of-the-art laser sources, we are enabling these technologies for both orbital and planetary missions.

The Laser Space Technologies team specializes in the research and development of advanced laser technologies for space applications. Our focus includes laser ablation in space and its applications, optical laser communications, and disruptive approaches such as power beaming and laser-based 3D printing.

We are equipped with state-of-the-art experimental infrastructure, including the pulsed laser system Bivoj, which holds several world records for output energy, a laser optics testing laboratory, an adaptive optics development facility, and a cryogenically cooled vacuum chamber for laser ablation. In our laboratories, we develop new types of optical components designed to withstand extreme conditions, and we also work on adaptive optics and the compensation of atmospheric turbulence in laser beam propagation.

We collaborate with industrial and international partners, including the European Space Agency (ESA) and the European Commission. Our team, composed of experts in laser ablation, adaptive optics, and optoelectronics, is gradually expanding to include specialists in signal processing and space-grade optomechanics. Our goal is to deliver technological innovations applicable to both orbital and planetary missions.

We actively seek direct involvement in European technology consortia and space programs. The Laser Space Technologies team represents an interdisciplinary fusion of physics, optics, and engineering for the future of space.

Learn about the ATLAS project.

DLA - Defence Laser Applications Team

DLA - Defence Laser Applications Team

The Defence Laser Applications (DLA) is our newest team, and one of the few that was established directly in response to industrial demand. Defence is becoming an increasingly important topic in our society, and at HiLASE, we intend to be part of it.

Defence technologies at HiLASE follow three main directions: laser technologies for manufacturing, laser communication, and long-distance energy transfer.

Within DLA, our ambition is to identify the needs for laser technologies in manufacturing across industries and then coordinate this collaboration in close synergy with other HiLASians.

It’s similar to laser communication technologies. Our application team tests and improves them in cooperation with industrial partners.

Everything is quite different when it comes to long-distance energy transfer. Laser weapons are a strategic item on NATO’s technology list, and we have several competencies in this area. We can, and want to, advise companies on how to build such a laser cannon, what they will need to do so, and ultimately, how much it will cost. But we can also stand on the other side, using our expertise to develop “laser shields.” Laser–material interaction is our daily bread, and we know this field not only in terms of welding or cutting, but, as it turns out, also for shooting down or protecting against targets.

So, if you are tempted to work on cutting-edge technologies with the ambition to contribute to the defence not only of our country but also of allied partners, and if you want to explore areas no one has before, joining our DLA team might be the right choice for you.