Engineering & Technical support

Engineering & Technical support

We design and develop mechanical and optomechanical parts, electronics, and control systems, including safety features. We provide a complete service from the initial concept through production, assembly, and commissioning to testing and certification. We support scientific teams and are responsible for the operation of the mechanical and electronic workshops. We love challenges and enjoy finding smart solutions to even the most complex technical problems.

DESIGN TEAM

DESIGN TEAM

From micrometer precision to structures tens of meters long. That’s what we do. We are a design team, and our job at the HiLASE Centre is to turn visions and ideas - sometimes just sketches with a few words - into metal, plastic, and glass.

We design and engineer everything from the tiniest components (M1.6 or M2 screws – do you use those often? We do.) to massive assemblies that span entire buildings. (Like our vacuum system for laser beam delivery, which is over 50 meters long and includes more than 10,000 parts.)

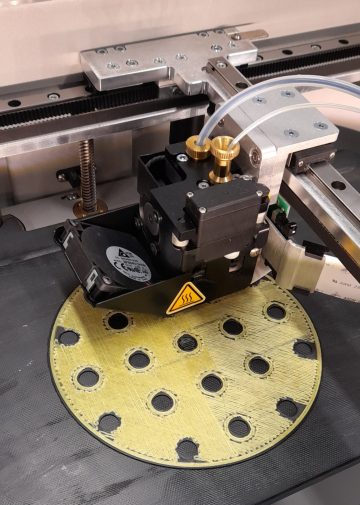

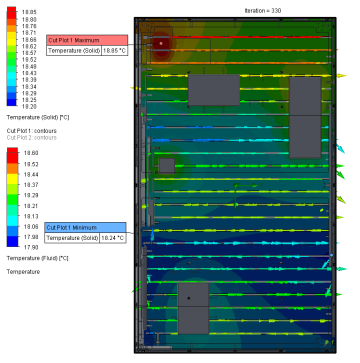

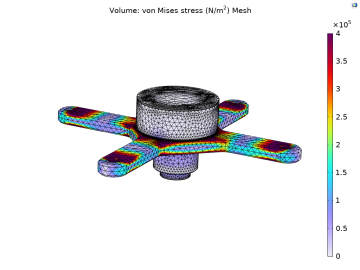

In between, there’s a whole range of optomechanical mounts, adapters, clamps, laser heads, safety covers and boxes, custom workstations, vacuum and pressure chambers, cooling systems, or heated ovens, processing stations, reducers, caps, experimental setups, and even door wedges. We simulate many of these – optically, mechanically, thermally, or in various combinations – and we also 3D print many of them.

Does it sound a bit self-congratulatory? Maybe. But is it true? Join us and find out!

ELECTRONICS DEVELOPMENT TEAM

ELECTRONICS DEVELOPMENT TEAM

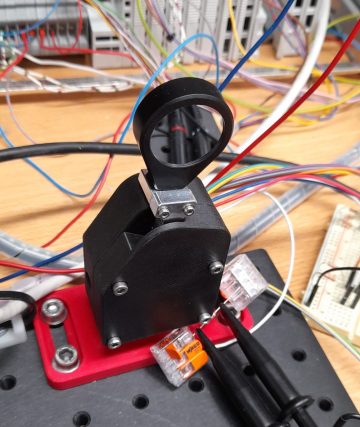

The electronics development team supports scientific groups by designing and building electronic prototypes for research and experimental use. It develops both analog and digital systems, modifies laboratory equipment, and closely collaborates with other engineering teams.

The electronics development team focuses primarily on providing technical support to scientific teams and developing electronic prototypes tailored for experimental and research applications. It plays a key role in designing and adapting laboratory instruments, creating measurement and control electronics customized to specific experimental needs, and ensuring rapid implementation of designs into practice. In addition, the team repairs electronic equipment used in laser systems, manufactures specialized jigs and custom one-off devices, and develops electronic systems for internal use.

Its expertise includes both analog circuit design and digital systems based on microcontrollers, targeting various industrial interfaces as well as modules designed for integration with PLC systems.

Close collaboration with the mechanical design and control systems teams is an essential part of the workflow, enabling seamless integration of all components in complex system solutions.

CONTROL SYSTEMS TEAM

CONTROL SYSTEMS TEAM

Our Control Systems team develops automated control solutions for cutting-edge laser technologies. We create reliable, safe, and user-friendly systems to make complex science run smoothly. Our main expertise lies in the design, development, and programming of industrial automated control systems for laser systems and laser applications.

We also focus on developing safety control systems – so-called laser interlocks – which ensure the safe operation of high-power lasers. We build on modern industrial platforms, especially the TwinCAT real-time environment and Beckhoff and B&R technologies, which allow us to deliver robust and reliable applications. In addition, we provide support for systems developed in the EPICS framework, widely used in international scientific infrastructures.

Our goal is to design and deliver solutions that are maintenance-free, reliable, and user-friendly, so that both users and developers can concentrate on research rather than troubleshooting technical issues.

Our work starts from the very beginning – selecting suitable hardware and designing electrical schematics, through the engineering and realization of switchboards in compliance with technical standards. The next step is programming the control system, which includes, for example, image processing, precise timing synchronization of laser pulses, and data acquisition from sensors such as photodiodes or laser power meters. The development process also involves programming automated sequences that enable users to operate the laser safely and easily with just a simple Start/Stop command.