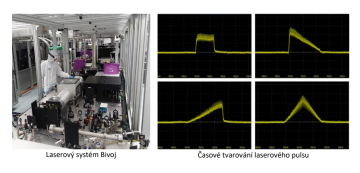

Time shaping of laser pulses for Laser Shock Peening technology

Abstract:

Laser Shock Peening (LSP) is a multidisciplinary process that lies at the intersection of laser physics, plasma physics, and materials engineering. It uses high-energy nanosecond laser pulses to generate compressive residual stresses in metallic materials. These materials are then characterized by longer fatigue life and generally higher resistance to cracks of all kinds.

In the LSP process, the laser pulse is focused by a lens onto the target material, where it is rapidly absorbed. This creates a rapidly expanding plasma, which leads to the formation of a strong pressure wave propagating through the material. The time course of the pulse plays a crucial role in the absorption of the pulse and the formation of plasma. By choosing the appropriate pulse shape, we can, for example, achieve higher power density limits, which results in higher generated pressure and thus a more efficient process.

The state-of-the-art experimental laser system Bivoj, located at the HiLASE center, serves this purpose. Using variable voltage on Pockels cells, Bivoj enables advanced laser pulse shaping, from basic shapes such as Gaussian, rectangular, and triangular to more complex shapes such as double pulses.

The aim of the work is to utilize the possibility of time shaping Bivoje pulses in the LSP process and to determine the relationship between the pulse shape and the achievable processing parameters. The main output should then be an optimized laser pulse shape that could be used in future LSP experiments.

The LSP effect of selected pulse shapes will be evaluated by means of residual stresses generated in the material, which will be measured using an X-ray diffractometer and a drill. At the same time, the influence of the pulse shape on the degree of plastic deformation of the sample surface will also be measured.

During the work, the student will become familiar with the process of pulse shaping in detail and is expected to actively participate in working with the Bivoj laser system and in evaluating the results of the experiment.

What do we offer?

- Flexible working hours adapted to your class schedule

- Hands-on experience with advanced laser technologies

- Expert guidance and mentoring from experienced researchers

- Access to a modern laboratory and a friendly team of colleagues

Number of vacancies for this topic: 1

Supervisor: Doc. Ing. Ladislav Pína, DrSc.

Consultant: Ing. Jan Kaufman, Ph.D.

Field: Physics, Applied Research

Type of work: Diploma thesis, Research task

Training workplace: HiLASE, Institute of Physics, Czech Academy of Sciences

Language: Czech, English

Location: Dolní Břežany

Join us and step into the fascinating world of lasers!

If you think we could work well together, send me your CV and a few words about why you would like to do an internship with us.

I look forward to hearing from you!

Jan

Please always include the following text with your email/letter so that we can process the information you send us:

I agree that my personal data sent to FZU AV ČR, v.v.i., with its registered office at Na Slovance 2, 182 21 Prague 8, may be used in accordance with Act No. 110/2019 Coll. exclusively for the purposes of job placement and maintaining a database of job applicants. This consent is given for a period of one year and can be revoked in writing at any time.

Contact