Flexible Laser Shock Peening

Abstract:

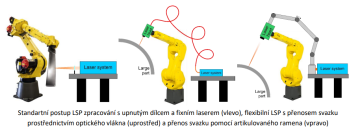

Laser Shock Peening (LSP) is a multidisciplinary process that lies at the intersection of laser physics, plasma physics, and materials engineering. It uses high-energy nanosecond laser pulses to generate compressive residual stresses in metallic materials. These materials are then characterized by longer fatigue life and generally higher resistance to cracks of all kinds. The main areas of application are industrial applications in aviation, energy, toolmaking, and 3D printing. LSP processing usually involves attaching the target part to a robotic arm, which moves the part along a defined path relative to a fixed laser beam. This approach has one major disadvantage. The weight of the parts being processed is limited by the load capacity of the robotic arm, typically around 35 kg. This limitation significantly narrows the application potential of the technology.

This raises the question of why the process cannot be reversed and a laser head used on a robotic arm and a stationary part. The reason lies in the parameters of the laser beam, specifically its diameter. The question arises as to why the process cannot be reversed and a laser head on a robotic arm and a stationary part used instead. The reason lies in the parameters of the laser beam, specifically the energy in the pulse (J) and its length (ns), which do not allow for simple transmission via optical fiber, which is the standard procedure for other industrial laser systems. The LSP process, in which we use a dynamic laser and a fixed component, is collectively referred to as “flexible LSP,” and its development is one of the main goals of the LSP group at the HiLASE laser center. Generally, two approaches to dynamic laser beam transfer are considered, namely using a specially developed laser fiber or a specially designed articulated arm with coupled mirrors.

The development of the fiber and articulated arm is already underway, and the doctoral student’s task will be to implement the individual approaches in the LSP laboratory and determine their theoretical and practical limits. Specifically, this will involve connecting the laser beam, transferring it to the laser head on the robot, and verifying the LSP effect on test samples. The beam will be characterized after passing through the system, with an emphasis on the transferred energy and accuracy at the laser head output.

The topic of the thesis is suitable for students who are interested in applied research and enjoy working in a laboratory. The topic is well defined with clear inputs and outputs, and the results of the thesis will certainly be used for real laser applications in industry.

What do we offer?

- Flexible working hours adapted to your class schedule

- Hands-on experience with advanced laser technologies

- Expert guidance and mentoring from experienced researchers

- Access to a modern laboratory and a friendly team of colleagues

Number of vacancies for this topic: 1

Supervisor: Doc. Ing. Ladislav Pína, DrSc.

Consultant: Ing. Jan Kaufman, Ph.D.

Field: Physics, Applied Research

Type of work: Dissertation

Training workplace: HiLASE, Institute of Physics, Czech Academy of Sciences

Language: Czech, English

Location: Dolní Břežany

Join us and step into the fascinating world of lasers!

If you think we could work well together, send me your CV and a few words about why you would like to do an internship with us.

I look forward to hearing from you!

Jan

Please always include the following text with your email/letter so that we can process the information you send us:

I agree that my personal data sent to FZU AV ČR, v.v.i., with its registered office at Na Slovance 2, 182 21 Prague 8, may be used in accordance with Act No. 110/2019 Coll. exclusively for the purposes of job placement and maintaining a database of job applicants. This consent is given for a period of one year and can be revoked in writing at any time.

Contact